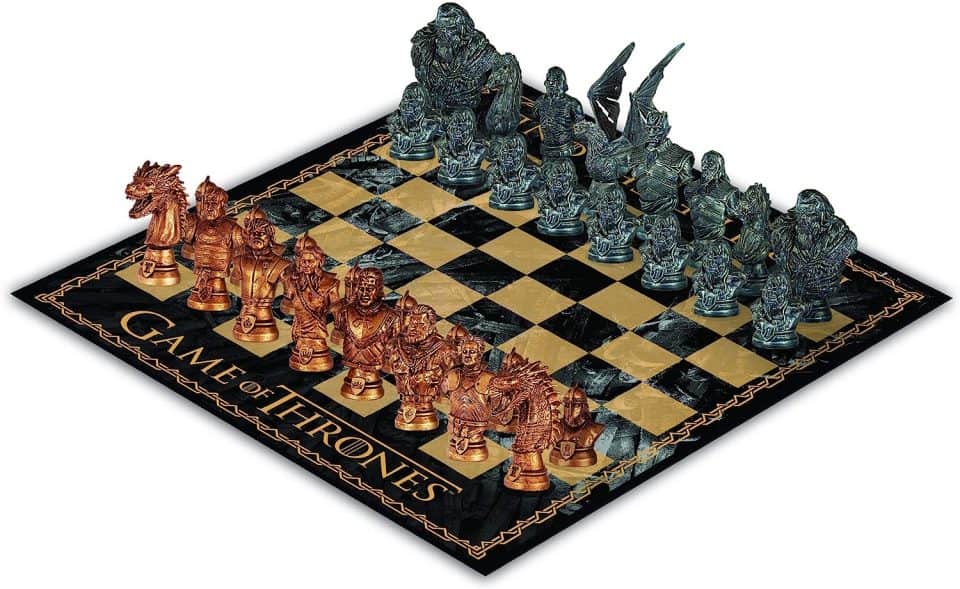

Chess pieces come in different forms: plastic, ceramic, aluminium or wood. Some of the luxury ones are even made with gold.

But among them all, the most aesthetically pleasing is arguably the wooden chess piece.

Wooden chess pieces are the preferred variety for chess games of the highest level. They bring elegance and beauty to the board.

Different types of wood can be used in the making of chess pieces but one of the best is the Rosewood from the Indian state of Chhattisgarh and Sheesham from Punjab.

India has been said to be one of the founding homes of chess and it is in this country that the best knowledge on how to carve chess pieces can be acquired.

Let’s go through the process together:

Preparing The Wood

Workers in Indian factories still maintain the old methods in making the chess pieces.

The wood arrives at the factories freshly cut. However, because they are freshly cut, they contain a lot of moisture.

Therefore they are cut into blocks with the aid of a cutting machine and sundried for a while under the hot sun.

The climate in India is usually very hot and this favours the creation of chess pieces.

Carving and Shaping

In recent times, the need for mass production and time constraints have restricted the hand carving of most chess pieces. Craftsmen use cutting and turning machines to create these elegant pieces.

To ensure consistency in design, special metallic tools like cutters specifically designed for every kind of piece are used. These cutters are carefully designed with a unique profile that corresponds to the shape of the chess piece they will make.

When creating intricate designs on wood, cylindrical blocks are rotated at a very high RPM against the turning tools. Various cutting and engraving tools are used to achieve the desired design.

Typically, it takes around 5-7 minutes to create a piece. However, the knight piece is an exception due to its complex shape and asymmetrical design.

Knights are the most beautiful of all pieces and as such, they are carefully handcrafted by skilled workers.

Each piece can take an entire day, however, expert craftsmen can turn out at least 4-7 knights every day.

Final Stage

After this stage, the chess pieces have taken form but they are not ready to play just yet. Weights are added to the pieces to keep them steady on the board. Nobody likes a wobbly chess piece.

To do this, a hole is created into the base of each piece and the weight is inserted and sealed. Next, felt is also added for the smooth and silent movement of the pieces across the board.

Finally, they are polished to give them the alluring shine and luster of a chessman.

They are then packed and sent to retail stores where they are sold to lovers of the game.

There you have it, folks.

Feel free to share your thoughts in the comment section.

1 comment

Khayrah

Nice work